Magnetism, the underlying principle behind electric motors and generators, relays and stereo speakers, is also the force that enables an important category of NDT tools called eddy current instruments. Eddy current testing is widely used in the aerospace industry and in other manufacturing and service environments that require inspection of thin metal for potential safety-related or quality-related problems. In addition to crack detection in metal sheets and tubing, eddy current can be used for certain metal thickness measurements such as identifying corrosion under aircraft skin, to measure conductivity and monitor the effects of heat treatment, and to determine the thickness of nonconductive coatings over conductive substrates. Both field portable and fixed system instruments are available to meet a wide variety of test needs.

Eddy current NDT can examine large areas very quickly, and it does not require use of coupling liquids. In addition to finding cracks, eddy current can also be used to check metal hardness and conductivity in applications where those properties are of interest, and to measure thin layers of nonconductive coatings like paint on metal parts. At the same time, eddy current testing is limited to materials that conduct electricity and thus cannot be used on plastics. In some cases, eddy current and ultrasonic testing are used together as complementary techniques, with eddy current having an advantage for quick surface testing and ultrasonics having better depth penetration.

How it works

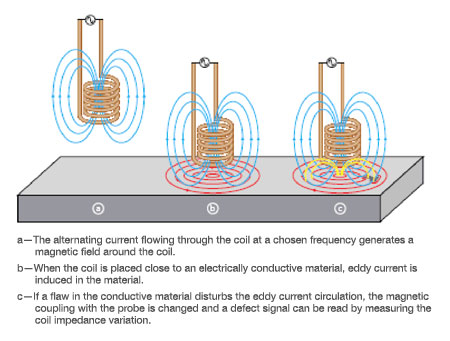

Eddy current testing is based on the physics phenomenon of electromagnetic induction. In an eddy current probe, an alternating current flows through a wire coil and generates an oscillating magnetic field. If the probe and its magnetic field are brought close to a conductive material like a metal test piece, a circular flow of electrons known as an eddy current will begin to move through the metal like swirling water in a stream. That eddy current flowing through the metal will in turn generate its own magnetic field, which will interact with the coil and its field through mutual inductance. Changes in metal thickness or defects like near-surface cracking will interrupt or alter the amplitude and pattern of the eddy current and the resulting magnetic field. This in turn affects the movement of electrons in the coil by varying the electrical impedance of the coil. The eddy current instrument plots changes in the impedance amplitude and phase angle, which can be used by a trained operator to identify changes in the test piece.

Eddy current density is highest near the surface of the part, so that is the region of highest test resolution. The standard depth of penetration is defined as the depth at which the eddy current density is 37% of its surface value, which in turn can be calculated from the test frequency and the magnetic permeability and conductivity of the test material. Thus, variations in the conductivity of the test material, its magnetic permeability, the frequency of the AC pulses driving the coil, and coil geometry will all have an effect on test sensitivity, resolution, and penetration.

There are many factors that will affect the capabilities of an eddy current inspection. Eddy currents traveling in materials with higher conductivity values will be more sensitive to surface defects but will have less penetration into the material, with penetration also being dependent on test frequency. Higher test frequencies increase near surface resolution but limit the depth of penetration, while lower test frequencies increase penetration. Larger coils inspect a greater volume of material from any given position, since the magnetic field flows deeper into the test piece, while smaller coils are more sensitive to small defects. Variations in permeability of a material generate noise that can limit flaw resolution because of greater background variations.

While conductivity and permeability are properties of the test material that are outside of the operator's control, the test frequency, coil type, and coil size can be chosen based on test requirements. In a given test, resolution will be determined by the probe type while detection capability will be controlled by material and equipment characteristics. Some inspections involve sweeping through multiple frequencies to optimize results, or inspection with multiple probes to obtain the best resolution and penetration required to detect all possible flaws. It is always important to select the right probe for each application in order to optimize test performance.

Impedance plane displays

While some older eddy current instruments used simple analog meter displays, the standard format now is an impedance plane plot that graphs coil resistance on the x-axis versus inductive reactance on the y-axis. Variations in the plot correspond to variations in the test piece. For example, the display below shows a setup for inspection for surface cracks in aluminum. The top curve represents a 0.040" deep surface crack, the middle curve is a 0.020" deep crack, and the smallest curve is a 0.008" deep crack. The horizontal line is the lift off in which the probe has been "nulled" (balanced) on the aluminum part and when it is lifted in the air, the signal moves directly to the left. This inspection is done with a pencil probe.

This display would be considered the calibration of the instrument. Once the parameters are set, they should not be changed during the inspection. The inspection measurements are dependent entirely on the comparison of the signal against the reference calibration.

Another common test involves measurement of nonconductive coatings like paint over metals. The screen display below shows a nonmetallic coating over aluminum. For this application, the probe is "nulled" (balanced) in air and then placed on the sample. The top line shows the signal on aluminum without any coating. The second line down is a 0.004" coating, then a 0.008" coating and the bottom line is a 0.012" coating. To create this image, the display position had to be changed between each measurement in order to display a separation between each signal. After this calibration is done, the inspector would measure on their parts and watch for the distance that the signal travels across the screen. Alarms could be used to alert the inspector when a coating is too thick or too thin.

A second way to measure the thickness of a nonconductive coating on a conductive material is using the conductivity measurement capability of the Olympus NDT N500 series instruments (N500C or higher). This measurement uses a special conductivity probe that displays the below screen instead of the standard impedance screen shown above. This measurement is most commonly used to determine the conductivity of a material but it will also provide the thickness of a coating which is considered the "Liftoff" from the material or how far the probe is above the surface of the conductive material. This example was a 0.004" coating on an aluminum test piece. Types of probes

Eddy current instruments can perform a wide variety of tests depending on the type of probe being used, and careful probe selection will help optimize performance. Some common probe types are listed below.

Surface probes - Used for identifying flaws on and below metal surfaces, usually large diameter to accommodate lower frequencies for deeper penetration, or for scanning larger areas.

Pencil probes - Smaller diameter probes housing coils built for high frequencies for high resolution of near surface flaws.

Bolt hole probes - Designed to inspect the inside of a bolt hole. These probes can be rotated by hand or automatically using a rotary scanner.

Donut probes - Designed to inspect aircraft fastener holes with fasteners in place.

Sliding probes - Also used in testing aircraft fastener holes, offering higher scan rates than donut probes.

ID probes - Used for inspection of heat exchangers and similar metal tubing from the inside, available in a variety of sizes.

OD probes - Used for inspection of metal tubing and bars from the outside, with the test piece passing through the coil

Reference standards

An eddy current system consisting of an instrument and a probe must always be calibrated with appropriate reference standards at the start of a test. This process involves identifying the baseline display from a given test piece and observing how it changes under the conditions that the test is intended to identify. In flaw detection applications, this calibration process typically involves the use of reference standards of the same material, shape, and size as the test piece, containing artificial defects such as saw cuts, drilled holes, or milled walls to simulate flaws. In thickness measurement applications the reference standards would consist of various samples of know thickness. The operator observes the response from the reference standards and then compares the indications from test pieces to these reference patterns to categorize parts. Proper calibration with appropriate reference standards is an essential part of any eddy current test procedure.

Common applications

Eddy current instruments can be used in a wide variety of tests. Some of the most common are listed below.

Weld Inspection - Many weld inspections employ ultrasonic NDT for subsurface testing and a complimentary eddy current method to scan the surface for open surface cracks on weld caps and in heat affected zones.

Conductivity Testing - Eddy current testing's ability to measure conductivity can be used to identify and sort ferrous and nonferrous alloys, and to verify heat treatment.

Surface Inspection - Surface cracks in machined parts and metal stock can be readily identified with eddy current. This includes inspection of the area around fasteners in aircraft and other critical applications.

Corrosion Detection - Eddy current instruments can be used to detect and quantify corrosion on the inside of thin metal such as aluminum aircraft skin. Low frequency probes can be used to locate corrosion on second and third layers of metal that cannot be inspected ultrasonically.

Bolt Hole Inspection - Cracking inside bolt holes can be detected using bolt hole probes, often with automated rotary scanners.

Tubing inspection - Both in-line inspection of tubing at the manufacturing stage and field inspection of tubing like heat exchangers are common eddy current applications. Both cracking and thickness variations can be detected.

Eddy current arrays

Eddy Current Array testing, or ECA, is a technology that provides the ability to simultaneously use multiple eddy current coils that are placed side by side in the same probe assembly. Each individual coil produces a signal relative to the phase and amplitude of the structure below it. This data is referenced to an encoded position and time and represented graphically as a C-scan image showing structures in a planar view. In addition to providing visualization through C-scan imaging, ECA allows coverage of larger areas in a single pass while maintaining high resolution. ECA can permit use of simpler fixturing, and can also simplify inspection of complex shapes through custom probes built to fit the profile of the test piece.

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDelete